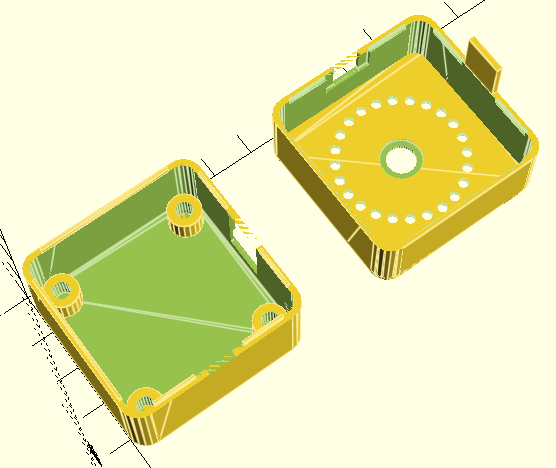

This is a simple 3D printed case for my Duppa I2C MIDI Controller PCB.

Warning! I strongly recommend using old or second hand equipment for your experiments. I am not responsible for any damage to expensive instruments!

If you are new to microcontrollers, see the Getting Started pages.

Parts list

- Duppa I2C MIDI Controller

- USB-C lead or serial MIDI.

- MIDI device

OpenSCAD Design

This uses some of the techniques from my Raspberry Pi 2,3,4 A+/B+ Synth Cases to define a basic box, then some cut-outs, and then to split the box and add some overlapping “lips” for a snap-fit.

There a number of functions to achieve this, but some of them are just collecting together the others in the right sequence.

- rounded – a basic “rounded” box module.

- standoff – the PCB supports.

- build_lips/build_lip – as expected, creates the overlapping lips. There is a parameter (solid) which determines if the lip is added to or subtracted from the case.

- base – the main box shape, less the actual top.

- top – the top plate that includes holes for the potentiometer and the LED ring.

- box – uses base() and top() to build a complete box.

- box_base/box_top – uses box and an intersection to produce the two halves of the main box.

At the top level box_base, box_top and standoff (four times) actually builds the complete case.

In terms of assumptions about the build:

- Most importantly, this assumes the use of PH5.0 headers to mount the Waveshare Zero device.

- It also assumes the use of a serial MIDI TRS socket.

- It should allow for M3 spaces and is build to assume two sets of 10mm spacers as described in the Build Guide.

Notes on printing:

- I found getting adhesion for the top with all those circular holes quite a challenge. In the end I increased the bed temperature and slowed the print right down to around 40% for the first layer and that seemed to improve thing quite a bit.

- Once complete I had to tidy up the LED holes a little by hand with a 2.5mm drill bit.

- The additional tag above the USB socket is quite delicate, so care is needed when snapping the case together.

Errata/Improvements:

- For my own build, the potentiometer shaft doesn’t stick out as much as I’d like. It is hard to find a knob that doesn’t have to be altered to fit and stay in place.

- I did wonder about using a thinner layer of 3D print over the LEDs rather than complete holes. I might still try that as an option to see how it works.

Closing Thoughts

This is a little tall, but I’m not sure what, in reality I could do about that. There might be some option for shrinking it a little, especially if the Waveshare Zero RP2040 is soldered directly to the PCB. But it would only save, maybe up to 6 mm in height, so it is probably not worth the effort.

But apart from that, this seems to have come out really well. The holes the LEDs I thought were perhaps a bit of a compromise, but actually they seem to work fine.

Kevin